We are the anti-corrosive coating solution for HVAC

INFINIGUARD® protects HVAC equipment by modifying the surface of exposed metals and encapsulating treated units with an ultra-strong, flexible, thin clear ceramic layer of siloxane. Once treated with INFINIGUARD®, equipment maintains like-new efficiency and is much easier to clean and maintain.

Cabinet

INFINIGUARD® goes on clear, giving treated cabinets a glossy finish. Brand integrity is preserved, while protecting equipment from the elements with a super-hydrophobic surface.

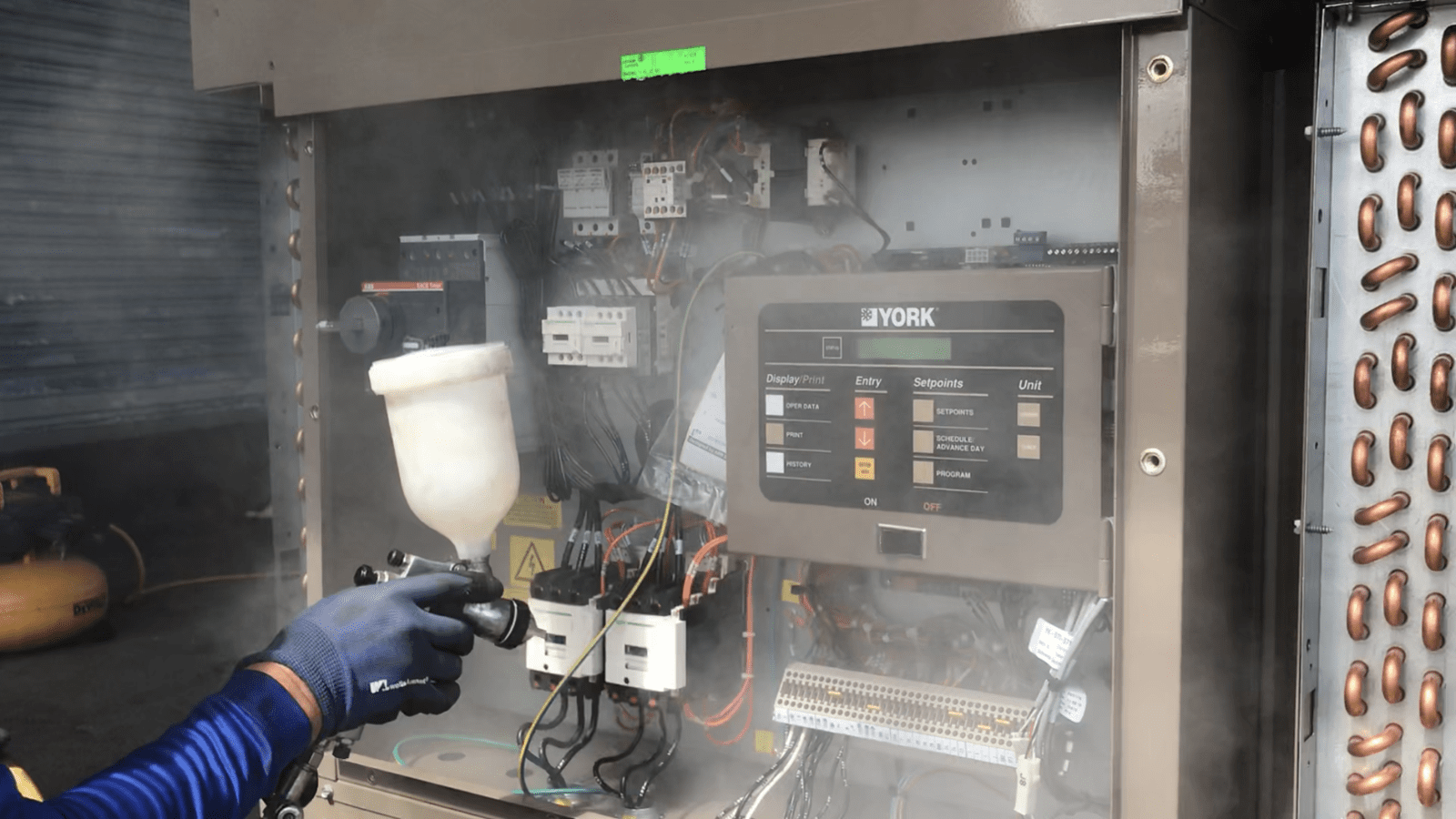

Control Panel

INFINIGUARD® creates a non-conductive surface, allowing it to be applied to control panels and logic boards with no issues. Electrical components can be protected from corrosion with a quick application.

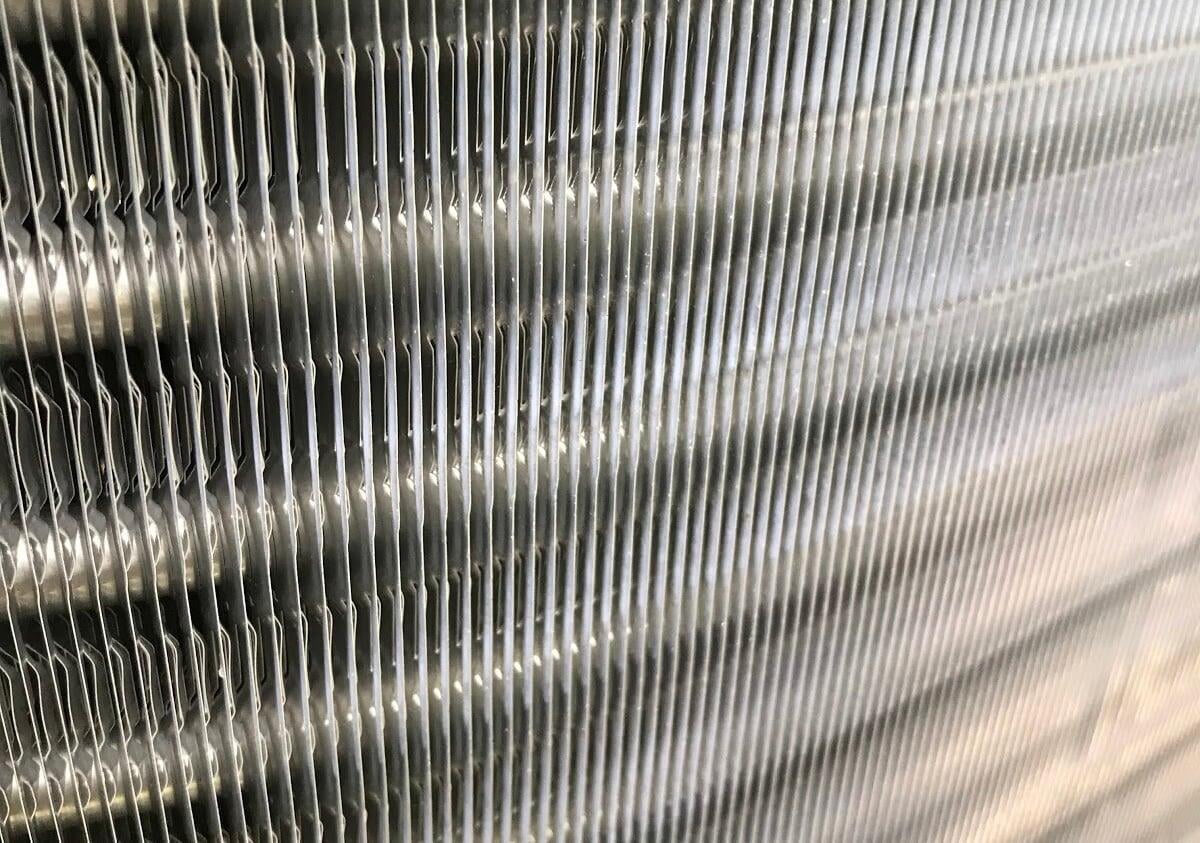

Coils

INFINIGUARD® is applied with an ultra thin (0.5 mils) layer, allowing it to be applied on all heat exchanger coil types (including micro-channel coils) with complete penetration and no bridging.

EN

EN ES

ES